The palm oil industry is a cornerstone of the economies of Malaysia and Indonesia, contributing approximately 85% of global palm oil production. Despite its economic significance, the industry faces significant challenges, including environmental concerns, regulatory pressures, and inefficiencies in production. However, advancements in technology offer transformative solutions that can address these issues while promoting sustainability and productivity.

Table of Contents

Challenges Facing the Palm Oil Industry

- Environmental Concerns and Deforestation

The palm oil industry has long been criticised for its role in deforestation and biodiversity loss. Large-scale plantation expansion often comes at the expense of tropical rainforests, contributing to habitat destruction and carbon emissions. The European Union Deforestation Regulation (EUDR), which requires proof that palm oil products are deforestation-free, has further amplified scrutiny on the sector.

- Low Yields and Ageing Plantations

A significant proportion of oil palm trees in Malaysia and Indonesia are past their prime productive years. For instance, around 30% of Malaysia’s oil palm trees are over 19 years old, leading to reduced yields. Replanting efforts remain insufficient due to high costs and limited access to quality seedlings, particularly for smallholder farmers.

- Smallholder Challenges

Smallholder farmers face unique challenges such as limited resources, lack of access to modern agricultural practices, and difficulties in meeting sustainability certifications like RSPO (Roundtable on Sustainable Palm Oil), MSPO (Malaysian Sustainable Palm Oil) and ISPO (Indonesian Sustainable Palm Oil).

- Regulatory Pressures

The EUDR and other international regulations demand traceability and compliance with stringent sustainability standards. While large plantations may already meet these requirements, smallholders often struggle with geolocation mapping, land ownership documentation, and deforestation-proof certifications.

Technological Solutions to Transform the Industry

To overcome these challenges, the integration of cutting-edge technologies is essential. Below are two transformative solutions that can revolutionise the palm oil industry:

Precision Agriculture with AI-Powered Satellite Imagery

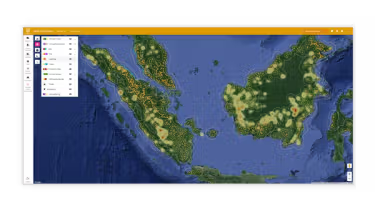

Precision agriculture leverages satellite imagery and artificial intelligence (AI) to enhance plantation management through real-time monitoring and data-driven decision-making.

- Aerial Surveillance and Crop Health Monitoring: Satellite imagery enables plantation managers to monitor vast areas efficiently, identifying issues such as pest infestations or nutrient deficiencies early on. This reduces reliance on manual inspections and minimises crop losses.

- Deforestation Monitoring for Compliance: Advanced geospatial technologies can map plantations and track land-use changes over time. This ensures compliance with sustainability certifications such as RSPO and EUDR by proving that no deforestation has occurred post-2020.

- Optimising Yields Through Data Insights: AI analyses can provide actionable insights on soil health, weather patterns, and optimal planting schedules. This helps maximise yields while reducing resource wastage.

Benefits of AI-powered Satellite Monitoring

AI-powered satellite monitoring is revolutionising plantation management worldwide by offering the following benefits:

- Deforestation Detection: Enables real-time monitoring to detect and address illegal deforestation activities, promoting environmental conservation.

- Crop Health Monitoring: Facilitates early detection of disease outbreaks, allowing timely interventions to improve yields and reduce losses.

- Land Ownership Documentation: Assists smallholders in mapping and documenting land ownership, ensuring compliance with regulations such as EUDR.

- Operational Efficiency: Reduces the need for costly, time-consuming ground surveys whilst covering vast plantation areas accurately.

- Sustainability Compliance: Supports adherence to international sustainability standards, boosting the industry’s environmental credibility.

- Cost Reduction: Helps optimise resource use and reduce operational costs through precise and data-driven decision-making.

These advancements highlight how satellite monitoring aligns operational efficiency with sustainability goals in the palm oil industry.

Sustainable Processing Technologies

Innovative processing methods can significantly reduce the environmental footprint of palm oil production:

- Zero-Waste Mills: These facilities convert waste products like palm kernel shells and empty fruit bunches into valuable by-products such as bioenergy, bioplastics, and animal feed.

- Solar Drying Solutions: Renewable energy-powered drying systems minimise reliance on fossil fuels while lowering operational costs.

How Solar Drying Works in Palm Oil Mills

Solar-powered drying solutions have been explored as a sustainable solution for processing biomass waste in palm oil mills:

- Solar Energy Collection: Solar thermal collectors capture sunlight and convert it into heat energy, which is then used to dry biomass waste such as empty fruit bunches (EFB) or palm kernel shells.

- Drying Process: The captured heat is transferred to air or other mediums, which are directed into drying chambers to reduce the moisture content of the biomass.

- Conversion to Bioenergy: The dried biomass is then processed into bioenergy products like biogas or biofuel, which can be used for mill operations or sold as renewable energy.

These technologies demonstrate how integrating solar thermal systems into palm oil mills can align environmental stewardship with operational efficiency and profitability by reducing reliance on fossil fuels, lowering greenhouse gas emissions, and supporting near-zero waste operations by turning waste into valuable resources.

Join our live session, “Revolutionising Drying with Solar Energy: Effective Solar Drying Solutions,” to explore how solar-powered systems are transforming industries through sustainable and efficient processing.

The palm oil industry in Malaysia and Indonesia faces challenges such as deforestation, ageing plantations, smallholder inefficiencies, and regulatory pressures. However, technology offers transformative solutions. By adopting AI-powered satellite imagery for precision agriculture and solar drying systems for sustainable processing, the industry can address these issues while advancing toward a sustainable future.

These innovations improve operational efficiency and ensure compliance with stringent sustainability standards. Embracing these technologies is essential for maintaining market leadership and securing a sustainable future for palm oil production in Malaysia and Indonesia.

Bernard Business Consulting is committed to supporting the palm oil sector through innovative solutions tailored to meet both environmental standards and economic goals. By embracing these advancements today, Malaysia and Indonesia can secure their positions as global leaders in sustainable palm oil production well into the future.

Explore our range of sustainable plantation solution now.